Concrete Repair

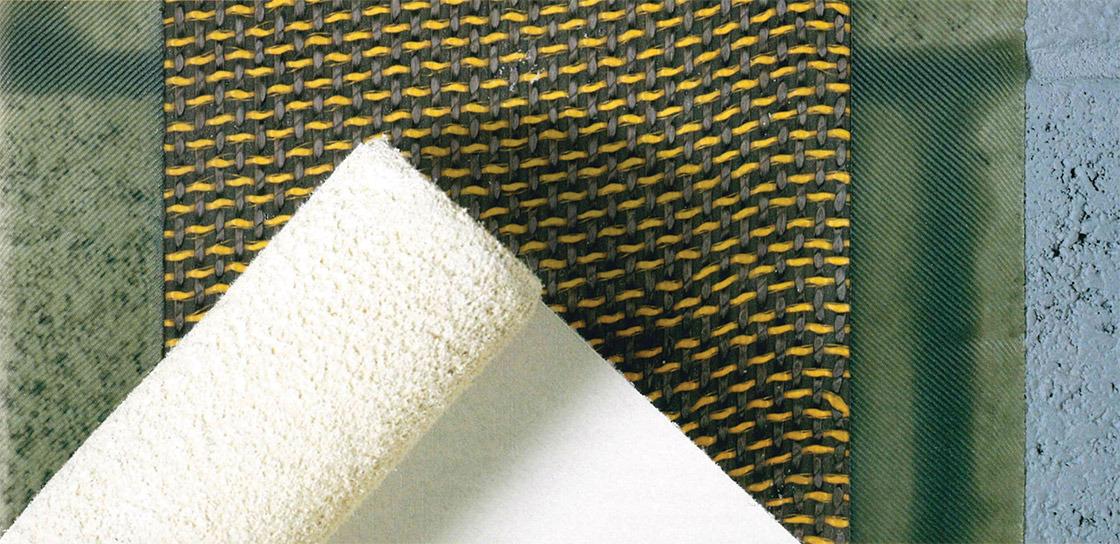

Carbon Fiber Concrete Stabilization System

Carbon Fiber Advantages

- Cost Effective

- Fast & Easy Installation

- Stronger than Steel – Up to 10X

- Will Not Rust or Deteriorate

- Can be Painted

- Versatile – Limitless Applications

LEARN MORE AT

www.fortressstabilization.com

Truex Preferred Construction specializes in structural concrete repairs using Carbon Fiber Technology.

Carbon Fiber is a proven alternative to steel for reinforcing structural substrates in residential and commercial applications. As certified installer for Fortress Stabilization Systems, Truex can assist with any project where these products may be applicable, such as:

- Concrete crack repairs

- Structural beam repairs

- Concrete balcony repairs

- Concrete tie beams/ columns

- Wall reinforcements

Protect the Life & Value of Your Investment

Truex Preferred Construction has the team and professionals needed to repair and protect your investment. Being a Certified Installer for Fortress Stabilization Systems , a distributor of carbon fiber materials, we have the knowledge and the experience to get projects done in a timely, cost-effective manner while saving our customer thousands of dollars and adding life and value back to their properties.

We specialize in repairing and reinforcing damaged or compromised concrete such as concrete cracks in walls, foundations, balconies, tie-beams and structural columns with Carbon fiber technology. This saves time and money compared to typical repairs.

Do you have a project that is in need of repair and do not know who to call? Call Truex Preferred Construction for a free estimate. From homes to various local condominium associations and commercial properties, we handle all types of projects from small to large.

Pre-Cast Lintel Repair

In the photo to the left, you can see the precast lintels are compromised from salt water intrusion. Once we remove the loose concrete, sandblast the rebar and apply a rust neutralizer we apply a bonding agent. We then apply a Sherwin Williams vertical overhead mortar. After it has cured the surfaces are smoothed into shape and thoroughly cleaned we can apply the Carbon fiber. A two part epoxy is rolled onto the area with a short nap paint roller saturating the surface.

A carbon tow sheet is precut and installed over the wet epoxy. After positioning another layer of epoxy is rolled over the surface to saturate the carbon and push out air pockets. 24 to 48 hours later the carbon repairs are ready for the finish, paint, stucco and spray texture.

Pre-Cast Hollow Core Panel Repair

Here is an example of the balcony issues we are seeing on coastal properties. Once water intrusion occurs, moisture and salt over time deteriorate the rebar causing it to expand and compromise the concrete.

The same cleaning, prep and carbon fiber two part epoxy process is used here.

The result, a dry, sealed, stronger structure with 40% less labor and installation than a typical repair, saving the customer thousands and protecting their investment.

Want More Information About Concrete Repair?

Call us today:

The History of Carbon Fiber

Until recently, carbon fiber materials were used extensively in the aerospace, marine, military and automobile industry. Now with the development of new manufacturing, increased production, and lowered costs, the field has expanded into the construction industry as well.

Replacing Steel with Carbon Fiber

Studies over the past 20 years have proven carbon fiber is highly effective at adding tensile strength to concrete. In fact, it is superior to steel because it is 10x stronger and non-corrosive. Because of this, carbon fiber has become a popular alternative to steel for structural reinforcement. It has the capability to bond to the surface to concrete to stop bowing and cracking. The applications are limitless in residential and commercial applications whether it be repair, retrofit, upgrades or new construction.